A Centralized Solution for Smarter Manufacturing

Optimizing Production with Real-Time Data, Automated Shift Planning, and Downtime Monitoring for Mesabi Control Engineering

The client needed a solution to remotely monitor and analyze productivity across facilities. They required a centralized system to track production without visiting each site individually. Mono developed a real-time, scalable platform that integrates production data to assess the productivity of machines, lines, and factories. The system includes features like OEE dashboards, downtime tracking, and shift planning, improving decision-making and operational efficiency.

Industry

Manufacturing and Industrial Automation

Company overview

Mesabi Control Engineering is a leading provider of automation systems for the manufacturing industry, specializing in control systems for production processes and recognized for over 30 years of expertise in the rubber manufacturing sector. It is a member of the HF MIXING GROUP, together with worldwide leading machine manufacturers Harburg-Freudenberger, Farrel and Pomini Rubber & Plastic.

The Challenge

The challenge was to create a system that effectively combines multiple functions, enables hierarchical data visualization, and provides real-time monitoring at the corporate level, all while maintaining strict data security and privacy compliance. The key challenges were:

Complex data visualization

The need for hierarchical data visualization to track performance across various levels of the organization.

Real-time monitoring

The requirement to monitor production lines in real time, with insights into machine status and downtime.

Resource and shift planning

A unified system was needed for efficient resource allocation and shift scheduling.

Data privacy and security

Strict privacy and security regulations had to be adhered to, given the sensitive nature of production data.

The Solution

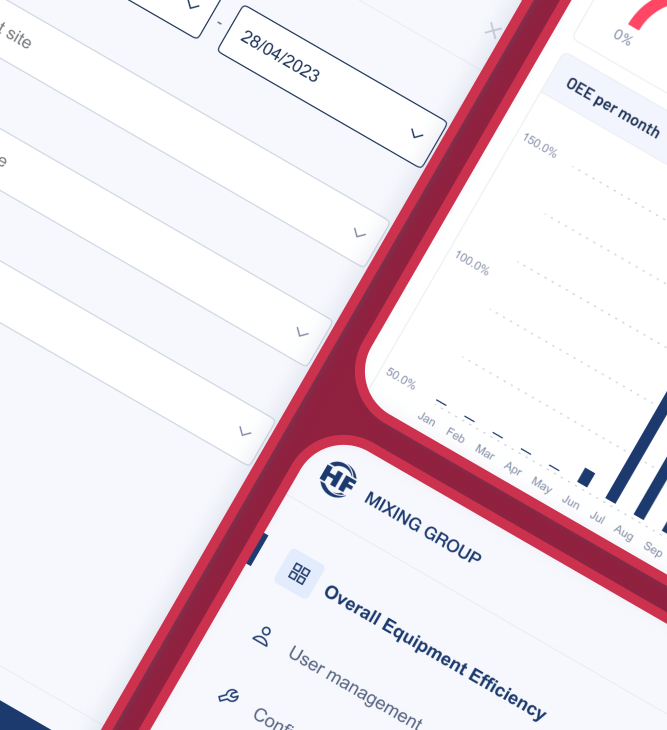

Mono developed a centralized production system designed to monitor, analyze, and manage production remotely, using a robust tech stack that includes ASP.NET Core for a scalable and secure web application, React for a dynamic user interface, PostgreSQL for reliable data management, and containerization for flexible deployment and streamlined scaling across facilities. The system integrates real-time data to calculate productivity across machines, production lines, and entire factories, delivering detailed insights that enhance both performance and decision-making.

The Key Features

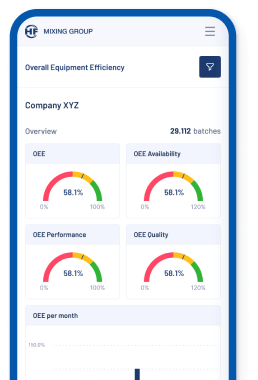

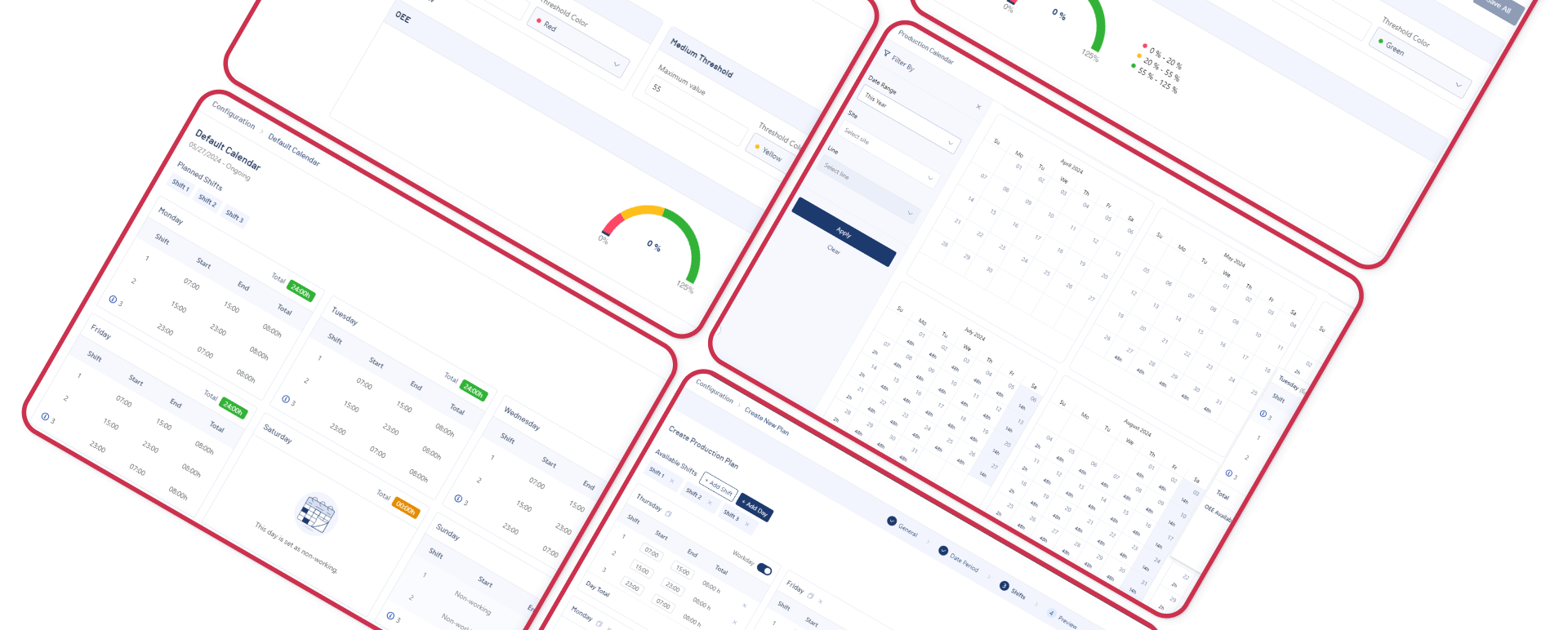

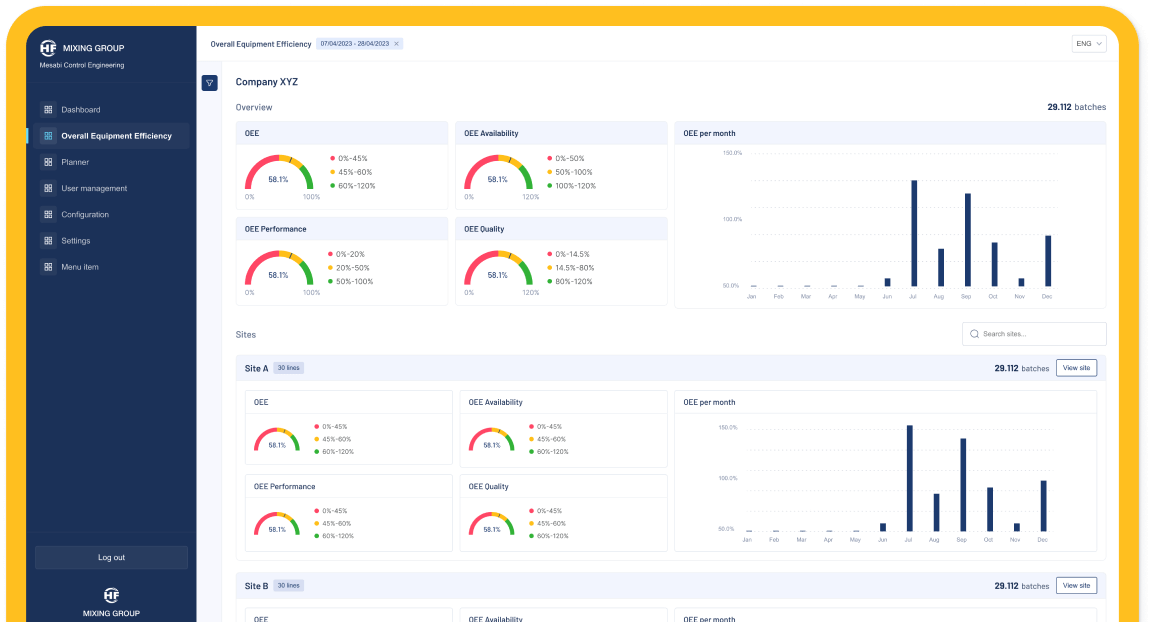

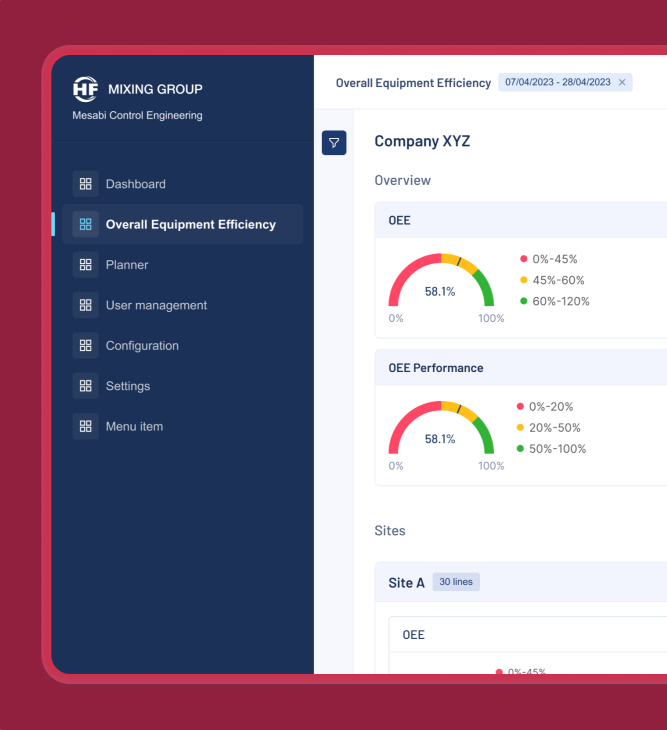

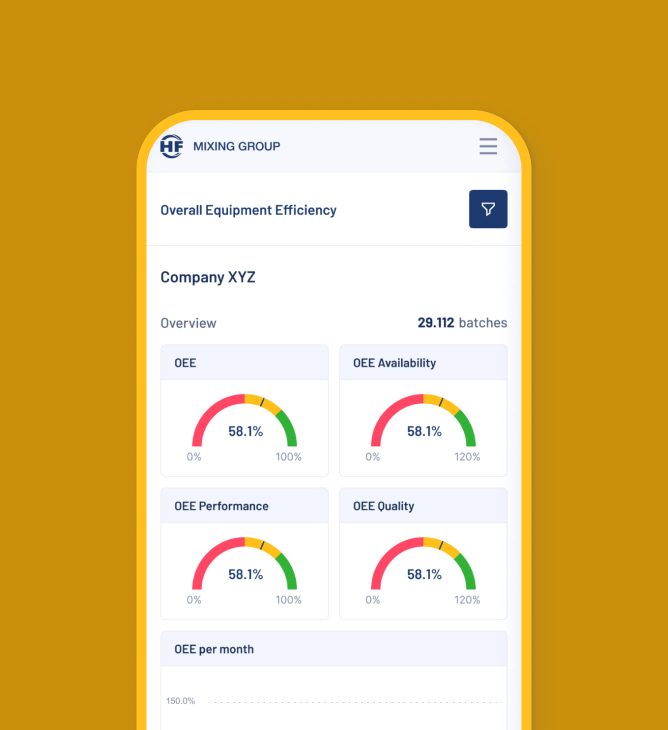

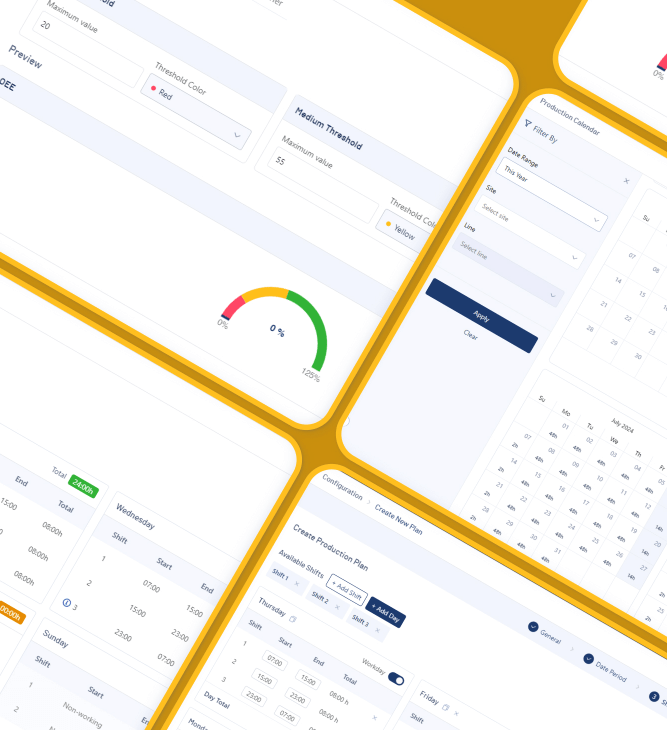

OEE dashboard

Provides an overall view of equipment effectiveness through intuitive visualizations, supporting both macro and micro analyses of production efficiency.

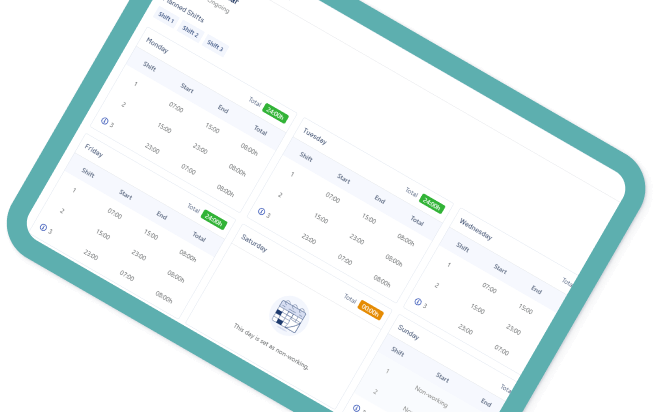

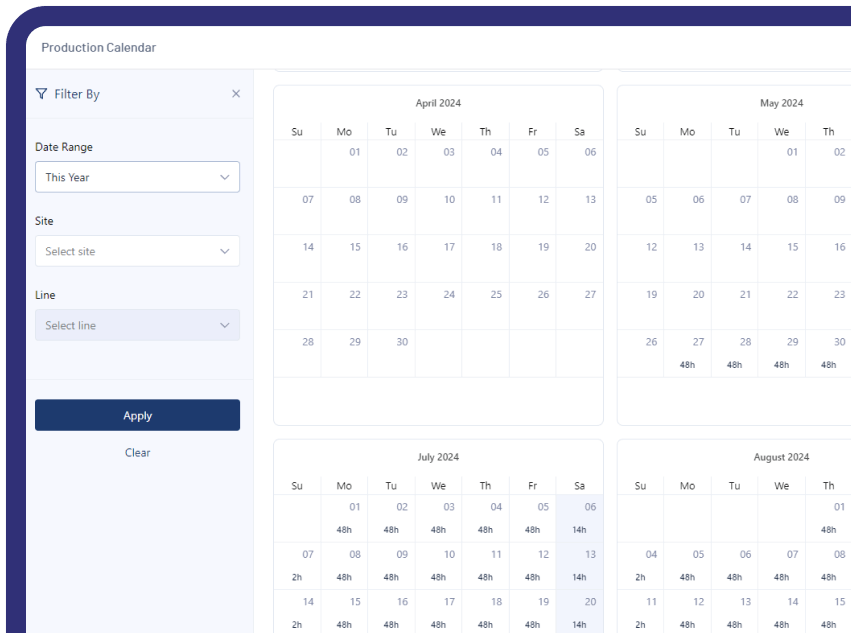

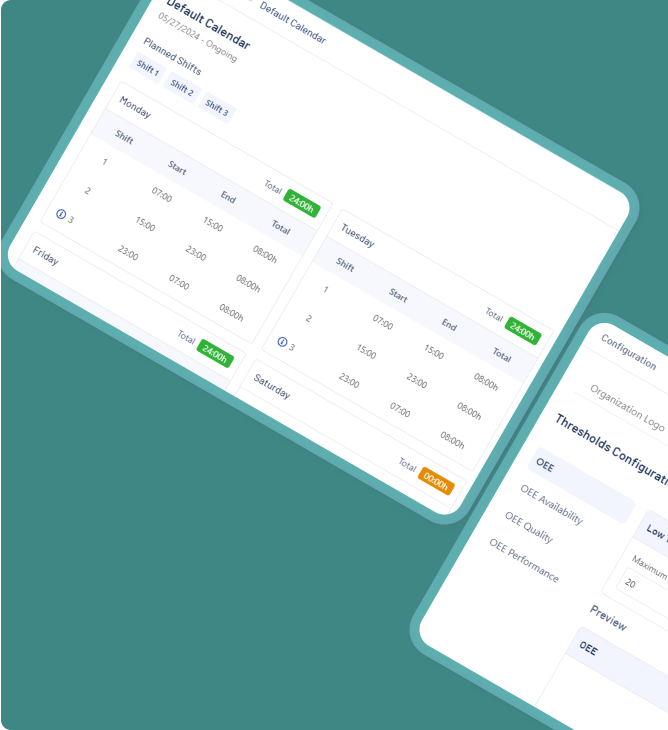

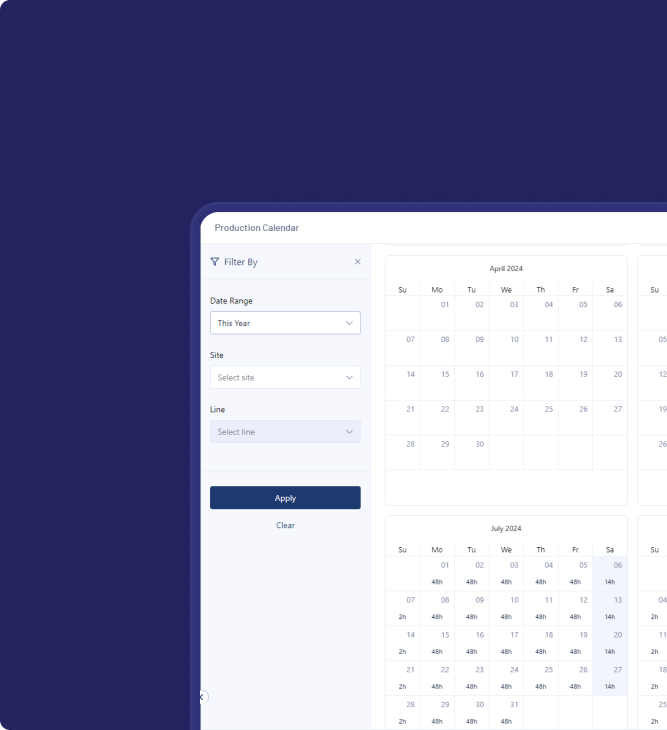

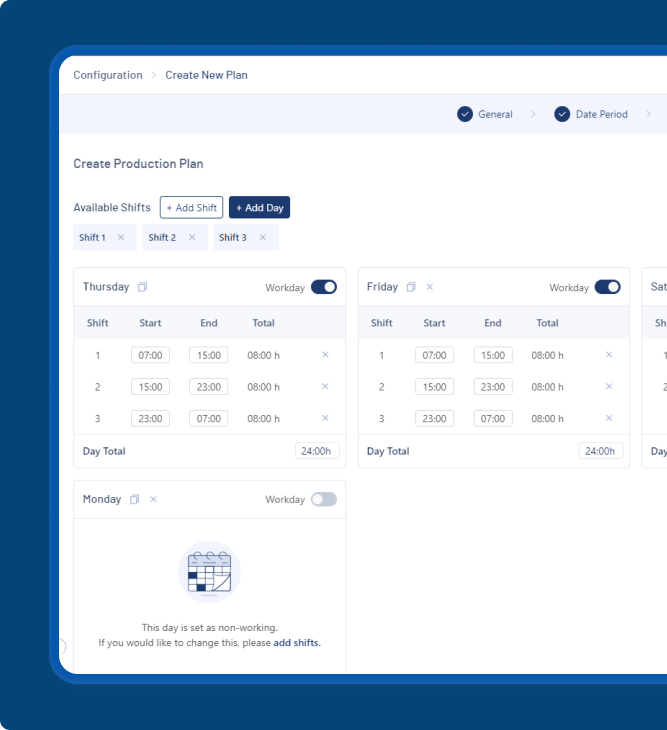

Shift production planner

Enables efficient shift scheduling and resource allocation, with a read-only interface for staff to view their schedules.

Downtime tracking

Helps identify and monitor machine downtimes, allowing for analysis and performance optimization.

API data collector

Securely handles data from external sources, ensuring seamless integration with other systems.

Multi-language support

Enhances accessibility by allowing users to select their preferred language for the application interface.

Live monitoring

Displays real-time production status across facilities, integrating data from multiple sources into one interface.

Results and Outcomes

The implementation of a centralized production system led to a substantial transformation in the client’s operational efficiency. By consolidating processes into a unified platform, the client experienced a marked improvement in coordination and workflow, allowing for smoother communication between departments and a more streamlined production cycle.

Key performance metrics indicated a significant reduction in delays and bottlenecks, enabling the client to meet production targets more consistently. Moreover, the system's automation capabilities helped to minimize manual errors, resulting in higher accuracy and overall product quality.

Reduction in downtime

Downtime tracking helps the client identify key problem areas, reducing unproductive periods.

Increase in production efficiency

Improved visibility and optimized resource planning streamline operations across multiple sites.

Enhanced data security

The system complied with strict data protection policies, ensuring secure handling of sensitive production data.

Improved decision-making

Real-time data and actionable insights from the OEE dashboard empower management to make better decisions.

Enhanced collaboration

Multi-language support and a user-friendly interface improve collaboration across teams in different regions.

Conclusion and Future Plans

The centralized production system has successfully addressed the client’s immediate challenges, enabling remote monitoring and optimization of production across multiple facilities. Looking ahead, Mono plans to integrate a comprehensive production and material management system, further centralizing operations and enhancing the client’s ability to oversee and manage production more effectively.

If your organization is facing similar challenges in production management, contact Mono today to explore how a custom-built centralized production system can help optimize your processes.

Testimonials

“Our working relationship with our co-development partner from Possehl Digital, Mono, has been productive and successful. The project started in earnest in mid-February 2024, and Mono was able to provide a functional MVP by mid-April. This timeline exceeded our expectations. Throughout the build process, we were provided with several status update meetings and given the opportunity to provide feedback. Mono's handling of the status meetings was clear and concise, providing a visual framework and the simulation of the workflow. This helped to assure us we were on the correct path, as well as with identifying any potential issues with our original concept.”

Ian Wilson, Managing Director, HF GROUP

Consult with us.

Let us know what kind of software you need. Our software development experts will have some ideas or advice on how to build it.